Made with a PTFE filtering membrane developed for the aerospace industry, these masks protect and last up to 10x longer than traditional n95 masks, while offering lasting 98% protection and 3x the breathability. Customize for your business or event.

Features of PTFE Mask Filter Material: PTFE filter material is composed of a layer of PTFE membrane with filtering characteristics and non-woven fabric with supporting function. The PTFE membrane is a porous structure with continuous porosity formed by many fine fibrils and nodes interconnected by fibrils. This structure not only retains the excellent high and low temperature resistance, low friction, non-stickiness, physiological inertness, physical and mechanical properties and chemical stability of PTFE materials, but also gives PTFE flexibility, fluid permeability, and fine particle trapping ability. Filterability, low dielectric constant and low dielectric loss tangent. Because of these special properties, this material has become a high-end fluorine-containing functional material.

The use of PTFE filter materials to manufacture masks has the following advantages:

Reusable: At present, most of the masks on the market use melt-blown as the core filter material. Melt-blown intercepts harmful substances through the principle of electrostatic adsorption, but as the use time increases, the filtration efficiency becomes lower, and it is usually recommended to use it for several hours. The PTFE filter material intercepts harmful substances through the principle of surface interception, and the filtration efficiency will not decrease with the use of time. In theory, it can be used repeatedly without damaging the physical structure of PTFE. Under normal circumstances, the filtration performance can be maintained for 200 hours, which is equivalent to at least 20 ordinary disposable masks based on 8 hours a day.

Convenient Disinfection: At present, the mainstream disinfection methods for self-use masks for residents include ultraviolet radiation and alcohol spraying, but the melt-blown material meets water and other liquids will reduce the filtration efficiency. For example, spraying the melt-blown material with alcohol will reduce the filtration efficiency of the melt-blown material by 15% -20%, Ultraviolet and other equipment will not be readily available in ordinary households, which makes disinfection very inconvenient. The PTFE material uses physical interception filter data due to the filtration principle, and the filtration efficiency of liquids such as water is not affected. It can be directly sprayed with alcohol for disinfection, which is very convenient.

Safe and comfortable: Those who have experience in wearing melt-blown masks know that if the mask is worn for a long time, there will be internal water accumulation, and the breathing valve installed for drainage will increase the exposure risk of the mask. This is because the melt-blown material cannot pass through the water vapor. At the same time, the trapped water vapor will also reduce the filtration efficiency of the melt-blown material and weaken the protective effect of the mask. The PTFE filter material can permeate water vapor, so there is no need to install a breathing valve and its ventilation effect is also very good, which not only ensures the ventilation effect of the mask but also does not increase the exposure risk of the user, and the use process is safe and reliable. Due to the improved breathability and the absence of water vapor retention, PTFE masks have good skin-friendly, when worn, the skin feels good, and has a comfortable experience.

At the same time, the test report issued by a third-party organization, in terms of the key index of filtration efficiency, the PTFE mask filter material produced by our company and the PTFE mask prepared from the filter material have met the GB2626-2016 (Filter Type Anti-Particulate Respirator) KN95 requirements.

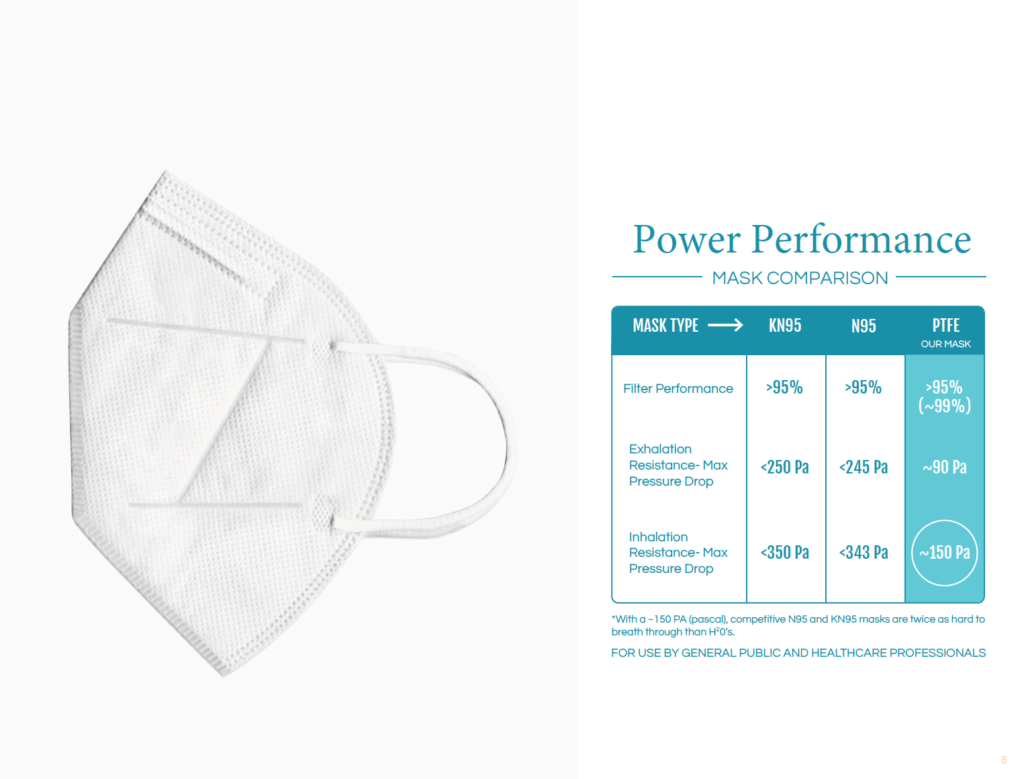

Table: Comparison of key parameters

| Filter Performance | Exhalation Resistance – Max Pressure Drop | Inhalation Resistance – Max Pressure Drop | |

| N95 Standard | >95% | <245 Pa | < 343 Pa |

| KN95 Standard | >95% | <250 Pa | <350 Pa |

| Our PTFE Mask | >95% (~98%) | ~90 Pa | ~150 Pa |